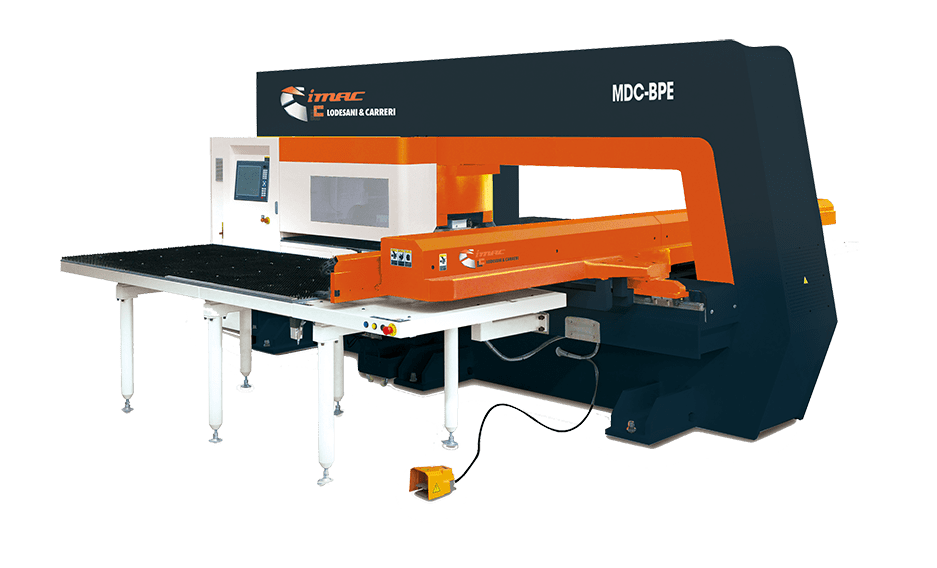

Sheet Metal Punching Machine - ITALY

Starting at INR 75L , high output machines

HPS - 450/ HPS 750 - BED size of: 1000x2000 / 1250x2000 / 1500x2000

HPS IMAC come in two models that work up to 450 or 750 strokes per minute.

The IMAC Punching Machines are equipped with:

C shaped rigid structure in electro welded steel. It is then subjected to a stress relieving heat treatment in order to guarantee a lasting stability of the structure and a perfect alignment between the punch and the matrix. Then it’s sandblasted and varnished,

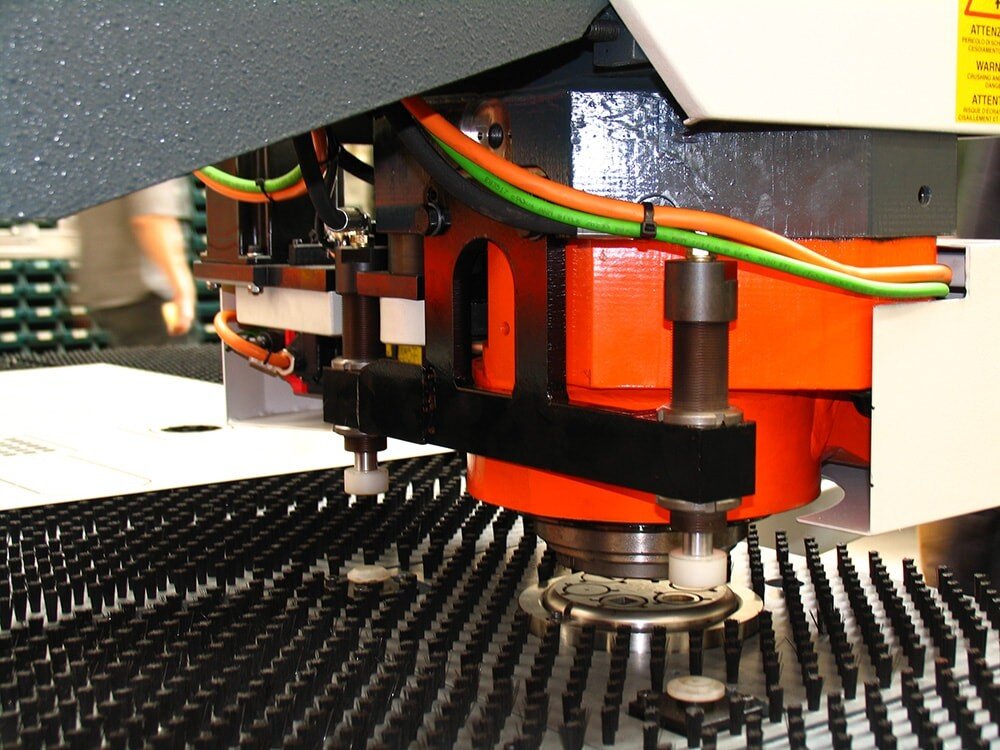

X axis: rectified guides with sphere recirculation screws, operated by brushless motors,

Y axis: 2 rectified guides with sphere recirculation screws, with brushless motors,

Z axis: hydraulic cylinder with adjustable punch stroke for each punch according to the sharpening condition and to the sheet thickness,

Excellent dimensioning of the working table,

Equipment high quality brushes fit on the working table,

Selector for the manual, semiautomatic or automatic working mode.

CNC S 500.R0135 numerical control,

The user can import and export programs on a USB key,

Ethernet port,

Selector for the working speed variation from 5% to 100%,

Quick changing system of the punch and matrix operated by hydraulic cylinders,

Anti-collision function between the pliers and the automatic piece taking up,

Automatic repositioning of the clamps up to 9999 mm calculated by the computer,

The blocking of the sheet takes place thanks to 2 hydraulic small cylinders,

The operator can change the repositioning speed in order to guarantee a high exactness during the repositioning operation,

Pedals for the automatic drive of the clamps

Wide box for the collection of the scraps.

The hydraulic power plant is located outside the machine in order to guarantee an easier and faster inspection.

For more information call us on +91 99721 55533 or +91 78920 28330

Or

Arrange for a call back from our sales team